12 Jul Could Freeze Drying Solve World Hunger?

With weather heating up this July, teapro’s fruit cooler box is firmly back on the menu. Gazing at our freeze dried raspberries we thought to ourselves, how misunderstood freeze drying is and also wondered if it held the answer to one of the world’s biggest problems.

How big a problem is world hunger?

Around 9% of the world’s population, a total of 690 million people are severely food insecure. Since 2014 this number has been slowly on the rise and by 2030 is expected to exceed 840million. Almost one third, 2.5 billion people have some level of hunger.

What about food waste?

Over 1/3 of all food produced globally goes to waste. In most developed countries, over half of all food waste takes place in the home. An average UK family throws away £700 worth of food per year, which collectively adds up to £14 billion per year.

This problem has a knock-on effect, which reaches way beyond food. For example, 25% of the world’s fresh water supply is used to grow food that is never eaten.

What makes freeze drying so great?

Freeze drying, (known as lyophilisation to scientists) is not just drying.

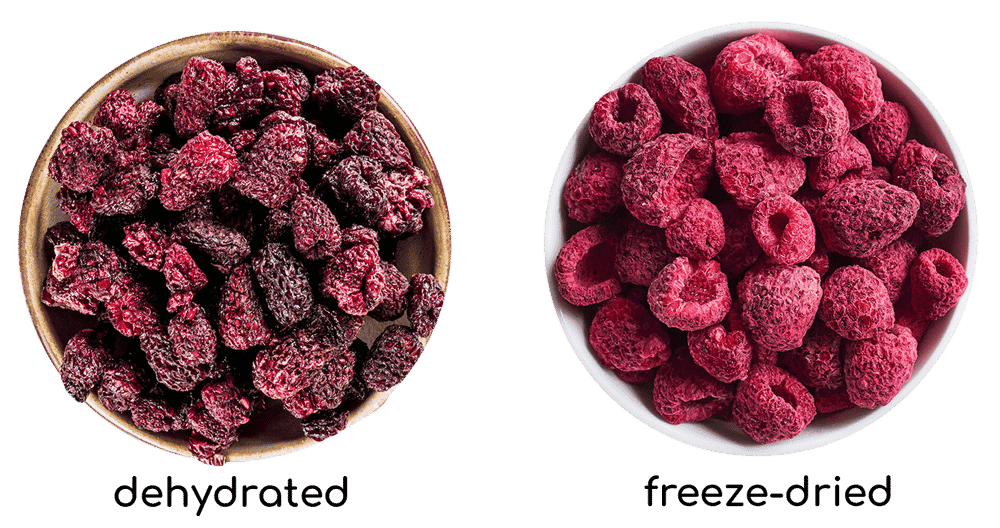

Drying or dehydration removes about 90% of the moisture from food such as fruits and this moisture removal enables the food to last between 15-20 years.

Freeze drying on the other hand removes about 99% of moisture and improves shelf life by 25-30 years. Freeze drying also retains far more of its vitamins and minerals. Another major benefit of freeze drying is that the fruit also retains its pre-dried structure, appearance and porosity unlike its more shrivelled counterpart. The texture of the food is even retained when re-hydrated.

So what actually is freeze drying?

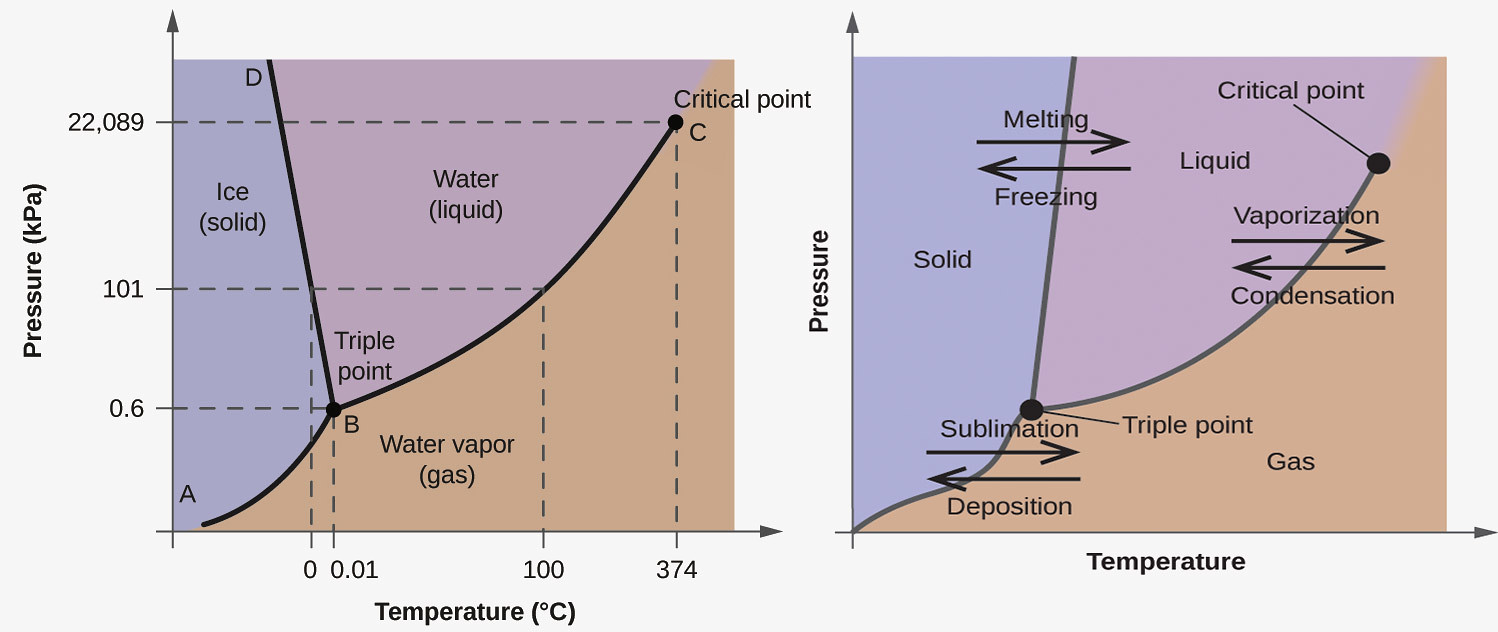

We all act differently under pressure. Water is no exception and when pressure is removed from water, it does some rather amazing things.

Step 1: Crystallisation

Crystallisation. The first step isn’t so surprising. The water in a food is frozen, forming ice crystals, which enables the water to be separated from the food stuff around it.

Step 2: Sublimation

The second step is somewhat magical and known as primary drying. By decreasing pressure using a vacuum to around .06 of our normal atmosphere and adding a small amount of additional heat, the ice crystals completely skip melting into water.

Instead it undergoes sublimation and jumps directly to a gas. This is because there isn’t enough pressure to form liquid water.

Freeze Drying therefore takes water below its rather exciting triple point, where water can occupy a solid, liquid or gas state and moves it directly over the border between solid and gas. Avoiding the liquid phase is what allows the structure of the food to be retained.

Step 3: Secondary drying

With 95% of the water already removed in primary drying, the final step involves a patient raising of temperature over a long period of time. This breaks any final bonds between food and water to remove any residual moisture.

A history of freeze drying

Freeze drying was first used by the Incas, who flourshed in Peru from 1438 to 1533.

The Incas were freezing potatoes on top of the chilly Andes mountains. Then, they would put their frozen goods under the hot summer sunlight, turning them into “chuño”, which roughly translates to frozen or wrinkled potato. Chuño is still very popular in Peru and Bolivia and is used to make chairo (a famous Bolivian soup), as well as many other dishes.

In Japan, a similar process was used by monks to preserve tofu, using the snow and low atmospheric pressure of the high altitudes of nearby mountains.

In 1906 Jacques Arsène d’Arsonval, considered the inventor of freeze-drying discovered the key process behind freeze drying, preceding the first recorded freeze drying using sublimation by Leon Shackell in 1909.

Freeze drying in medicine

Earl W. Flosdorf had freeze-dried human blood serum and plasma for medical use in 1933 and extended the technique to food. Ronald I. N. Greaves was the head of the research team who developed freeze drying and the method to freeze drying liquid.

During WWII, freeze drying was used to transport plasma as it was safely preserved, making travel easier as it isn’t heavy and easy to rehydrate without losing quality.

The invention of instant coffee

In 1965 Nestlé released the first freeze-dried instant coffee and freeze-dried ice cream was launched into space aboard Gemini in 1965 and Apollo 7 in 1968.

Freeze drying in modern times

Today Pfizer is considering freeze drying the vaccine in the United States to facilitate access in rural areas that might not have the required equipment for keeping the vaccine at sub zero temperatures.

So is freeze drying the future of food and solution to world hunger?

There is enormous interest in the future of freeze drying as the world adapts to increasing populations and less stable food production due to climate change.

Freeze drying could well be a part of the solution by increasing the shelf life of our food products whilst maintaining its nutrition and form.

Currently the cost and energy involved in freeze drying foods is high. A freeze drying machine for your home varies from $1,995 and $38,000+. Then there is maintenance and electricity costs which are up to 8 times higher than air dry methods.

commercial freeze drier

home use

With increased clean, renewable energy usage and improvements in technology and prices there is however a huge potential for the technology going forward.

Perhaps the image of freeze drying food also threatens to hold back its adoption with Chef’s like Gordon Ramsay berating any chef who reaches for a frozen food item.

We feel we should be looking seriously at technologies that can minimise our rampant food waste problem and use freeze-drying as part of the solution to improve food hunger outcomes around the world.

Teapro co-founder. Favourite tea - Long Jing Dragon Well Green Tea. Obsessed with film, photography and travelling.

- November 6, 2021

- October 27, 2021

- January 8, 2021

- August 7, 2020

No Comments